We are proud to introduce New Generation Needles for Tasteless Smoke "TS" and Carbon Monoxide

"CO"

treatment

of seafood. Needles are the most important element in manufacturing high-quality

gas-treated products.

New Generation Needles are the state of the art needles producing superior results.

Three types of Needles

Perfect coloration without needle mark or broken meat.

Super anti-clogging needles for intensive mass production.

Anti-clogging with optimal Liquid distribution.

Razor Sharp

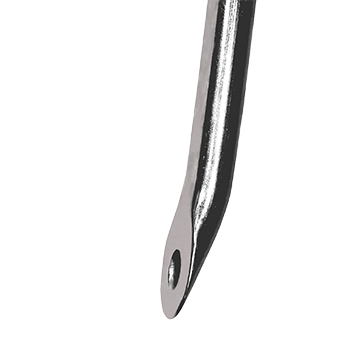

Model NG45 Needles

The NG45 is an

all-purpose

needle, producing flawless coloration without

needle marks,

or broken meat. Piecing sharp and will not damage the most delicate seafood

meat.

Manufactured with microscopic precision.

NG45 needles have a razor-sharp needle tip

with a mirror-polished anti-friction 316 shafts

that glide through the meat

without causing

softness or needle marks.

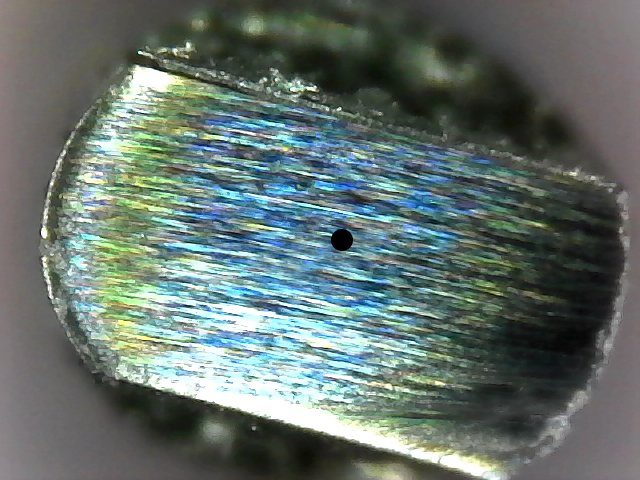

Crimp needle orifice (easy to clog)

DO YOU KNOW?

More than 60% of “Crimp Style” orifices

clog at the entryway to

the needle,

causing the needle tip to automatically clog,

resulting in treatment

defects.

NG gas injection needles have a “laser” precision

round-shaped

orifice that resists clogging.

The laser orifice provides a precise gas dosage

throughout the seafood, regardless

of the hard or soft parts of the meat.

The round-shaped orifice is not easy to clog

and

extends the needle life more than

double the crimp style orifice.

Cut-away view of NG round laser micro-orifice

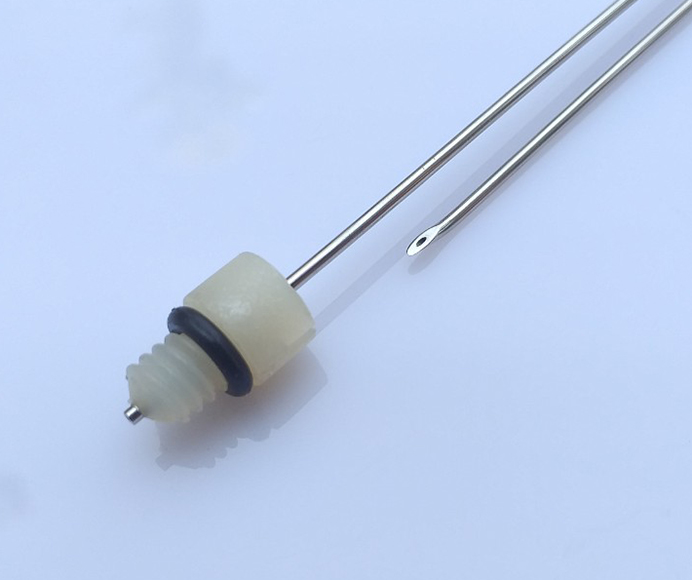

316 STAINLESS STEEL FILTER

A revolutionary NEW 316 Stainless steel filter provides 100% protection to clogging of the micro - orifice.

The 316 filter removes particles from the gas stream

that will clog the orifice or contaminate

the fish.

Life span of the needle is increase by at least 100%.

INVISIBILITY

The increased stiffness of NG needles avoids bending of the needle in the meat, which will tear

the flesh (like a cheese cutter).

When the needles are extracted from tuna loin, the needle

marks are erased and invisible.

STRONG AND LONG-LASTING

NG needle shafts are made with a hybrid

316 stainless steel that resists bending and corrosion.

Needle shafts have a thick wall construction that

provides 2-3 times increased strength and

resilience.

NG gas needles are many times stronger and

longer-lasting than other needles.

All NG needles utilize Huber tip technology,

with the

gas discharge hole on the side

of the needle, to prevent

the meat from

blocking the fluid pathway.

The hollow inner barrel of the needle

is polished to prevent

the meat from

sticking and promoting sanitation.

NG90 needles are precision crafted super anti-clogging needles with an advanced Huber needle tip design that will not fail under extreme high volume mass production conditions.

The unique sharp 90-degree bend and a small hole

on the side of the needle tip

has proven to be highly resistant

to clogging for super high mass production applications.

The NG90 gas needles are equipped with a 316 stainless steel filter mounted in the hub for reliable performance.

Calibrated for exact gas dosage,

to maximize coloration,

and minimize cracks in the meat.

A mirror-polished anti-friction shaft

glides through the meat.

316 stainless steel filters ensure

unparalleled performance

and reliability.

Perfect Treatment Results.

• Flawless coloration

• No broken meat

• Never needle marks

NGL needles are specially

designed for liquid, ideal for

brine

or anti-oxidant injection.

NGL needles have a thick wall needleshaft construction.

The hollow inner - diameter is an optimal

size to administer

a precise

quantity of liquids injected that promotes processing economy and quality of the final

treated products.

NGL needles have an anti-clogging Huber

needle tip

and boast a

polished hollow inner barrel that is easy to clean

and controls bio-hazards.

Find peace of mind in mass production with Tuna Technologies