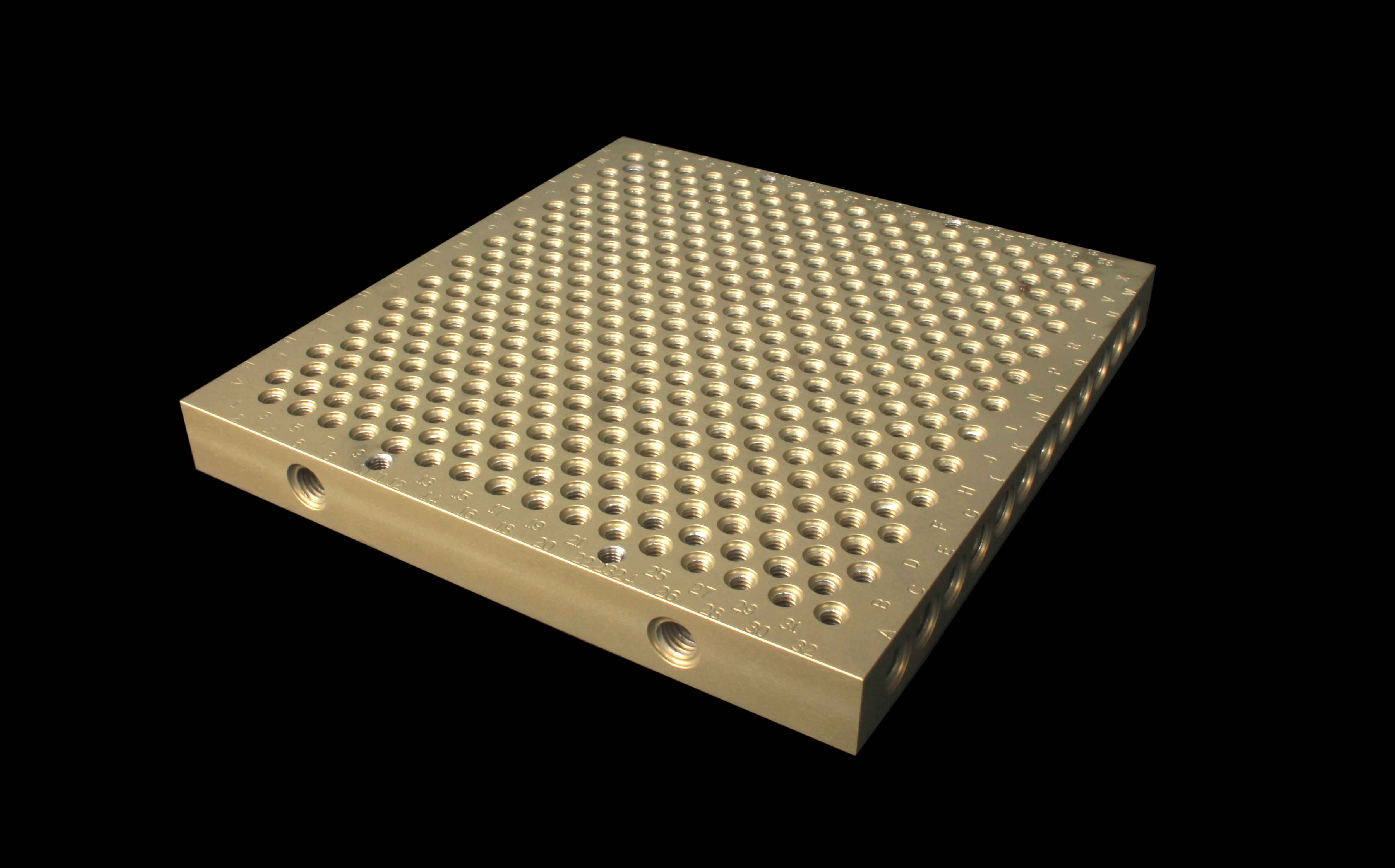

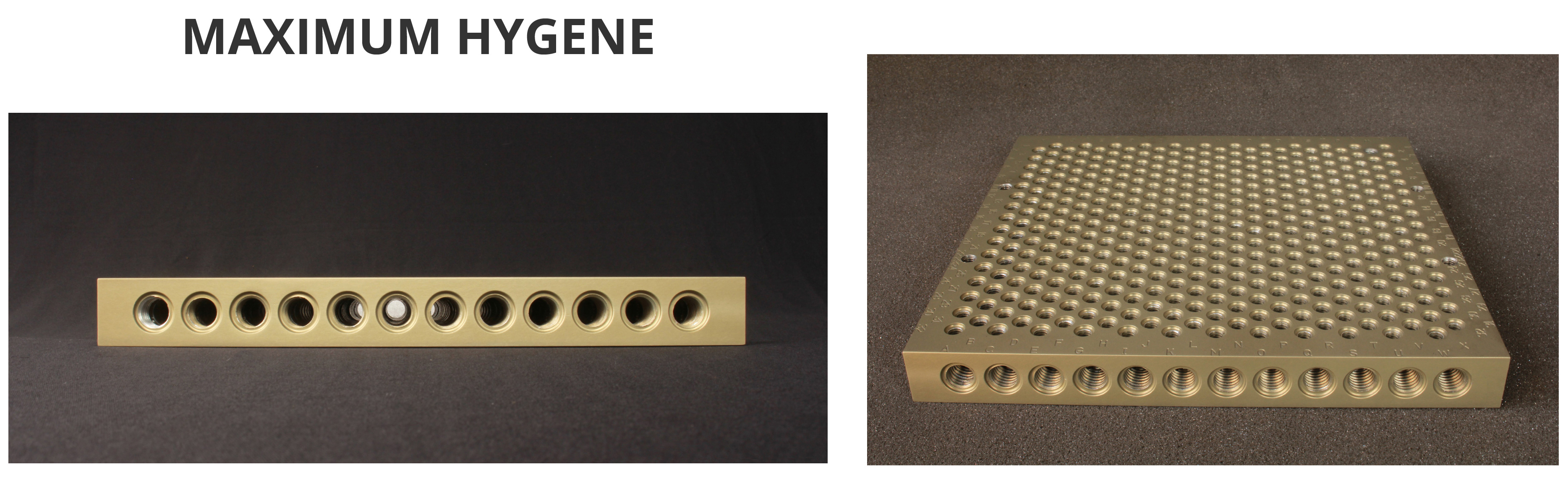

MODEL - MF384

Constructed of a durable aluminum alloy with a hard-anodized surface that is corrosion-resistant, easy to clean, and prevents oxidation inside the manifold that will clog needles and contaminate food.

The MF 384 is a high performance manifold for mass production of seafood treated with Tasteless Smoke " TS " or Carbon Monoxide " CO " gas.

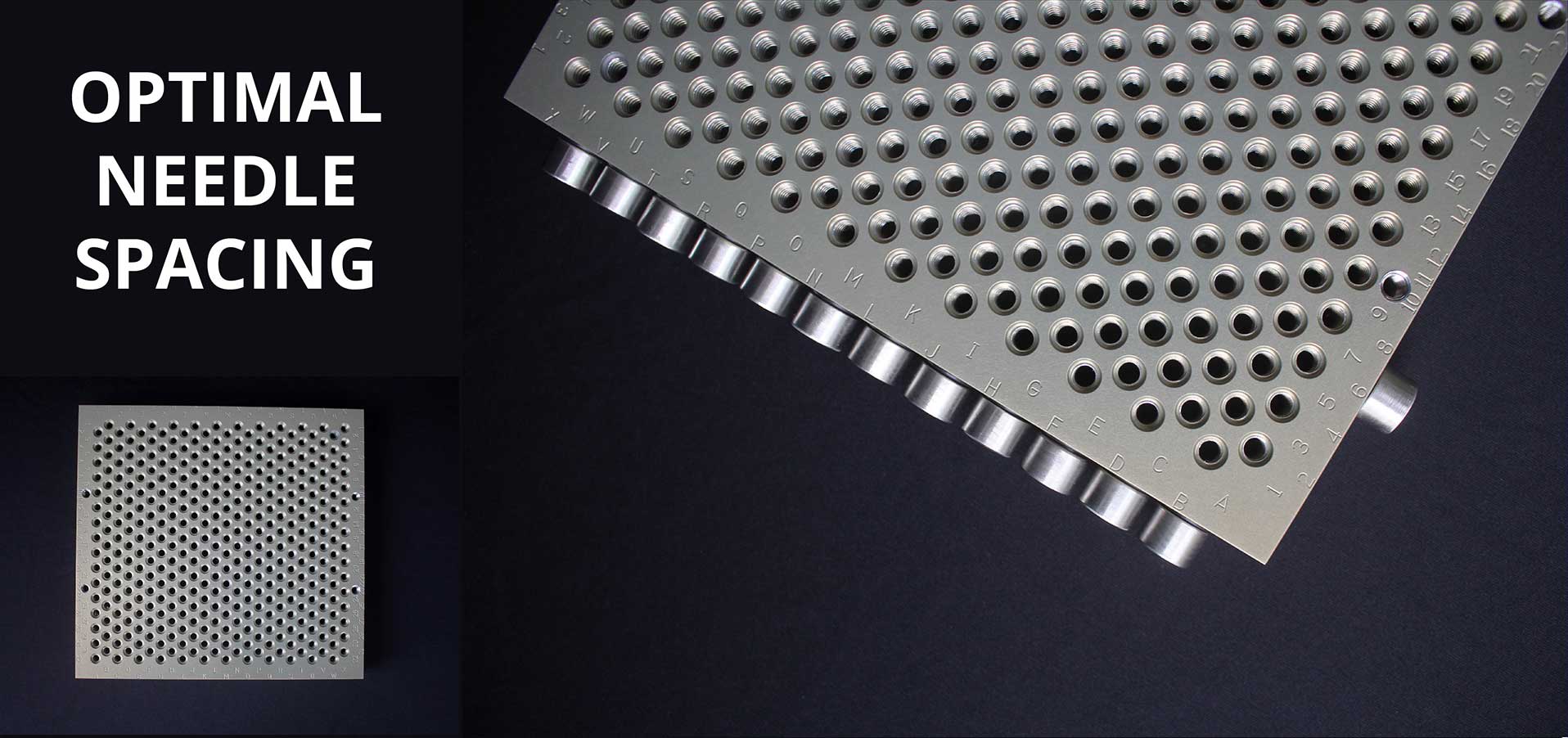

Mounting 384 stragetically spaced needles, which is

the optimal configuration

for reliable mass production.

Needles are spaced close together so

that a precise

dosage of gas can be

distributed throughout the meat.

The complete treatment is achieved

in less time

maximizing freshness,

while needle marks are invisible.

Close needle spacing is essential for

TS production because

TS contains a

lower concentration of CO.

Less CO means TS can not bridge wide gaps of meat that inevitably occurs from clogged needles causing unsightly defects.

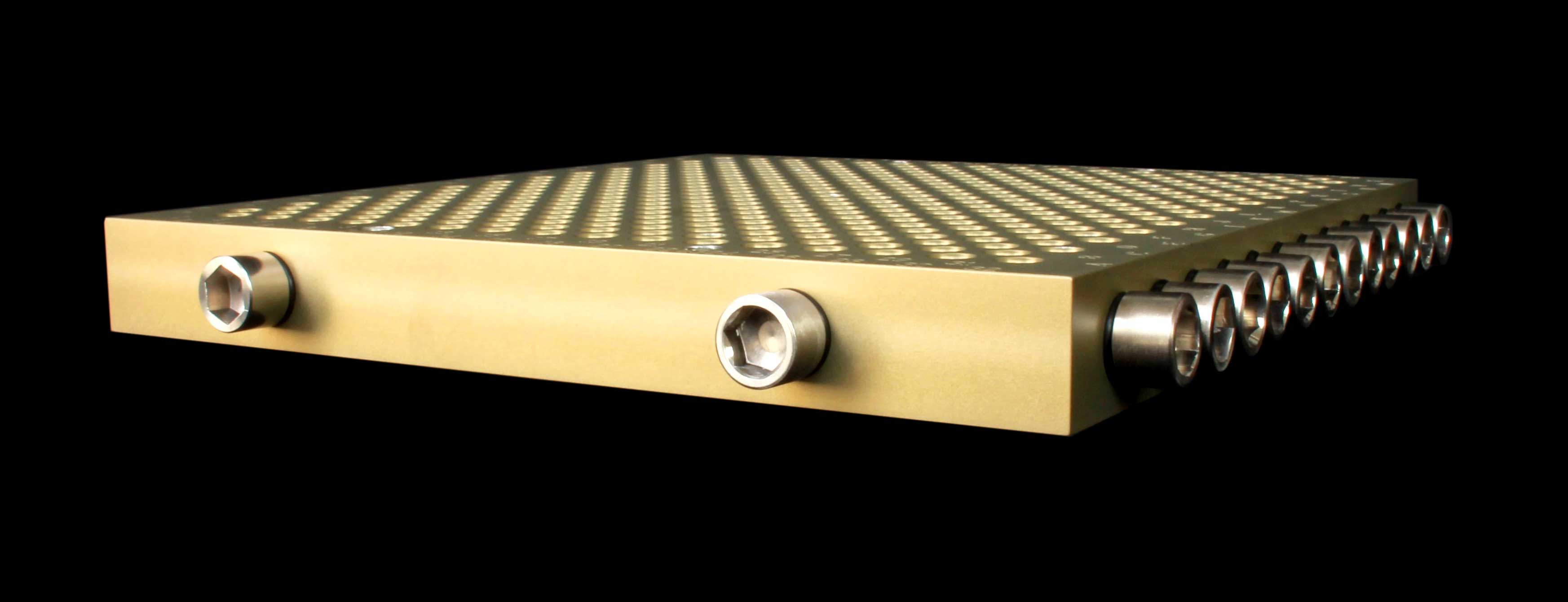

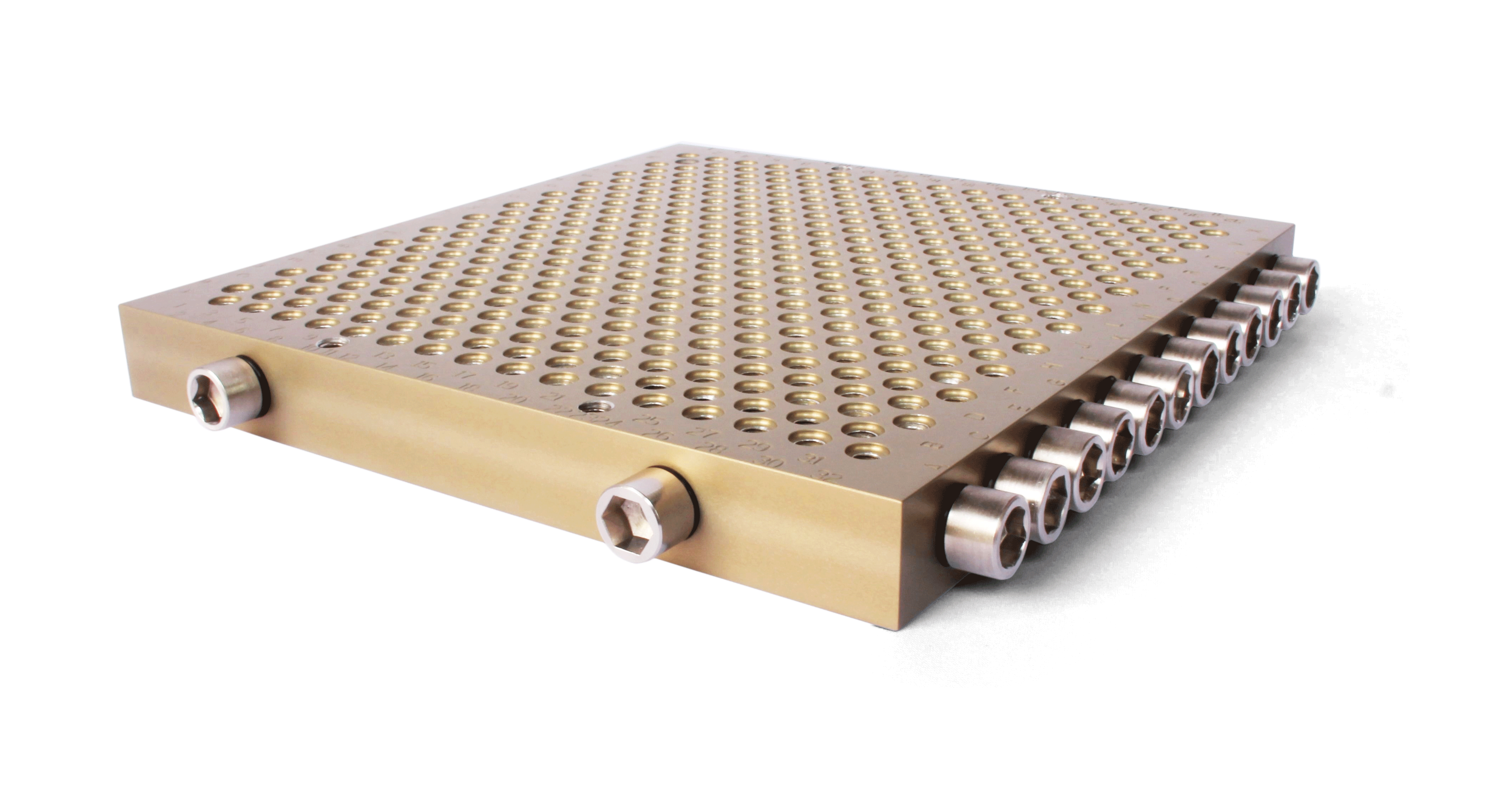

INDIVIDUAL NEEDLE REPLACEMENT

The MF 384 displays a needle number index for rapid replacement of individual clogged needles. Compatible with all injection machines in the market. Enabled to interface with the Revolutionary CLD 384 - Automatic Clog Detector device.

Manifolds made by other manufactures have a sealed gas chamber that becomes a junkyard for debris that clogs needles, plus a breeding ground for mold, bacteria, and viruses that can contaminate fish.

The sleek and sanitary through-hole internal chamber design of the MF384 facilitates thorough cleaning and increased ultrasonic washing functionality. Robust stainless steel plugs ensure maximum performance under high-pressure conditions. Chamber spaces inside the manifold are minimized for rapid pressure stabilization.

Find peace of mind in mass production with Tuna Technologies