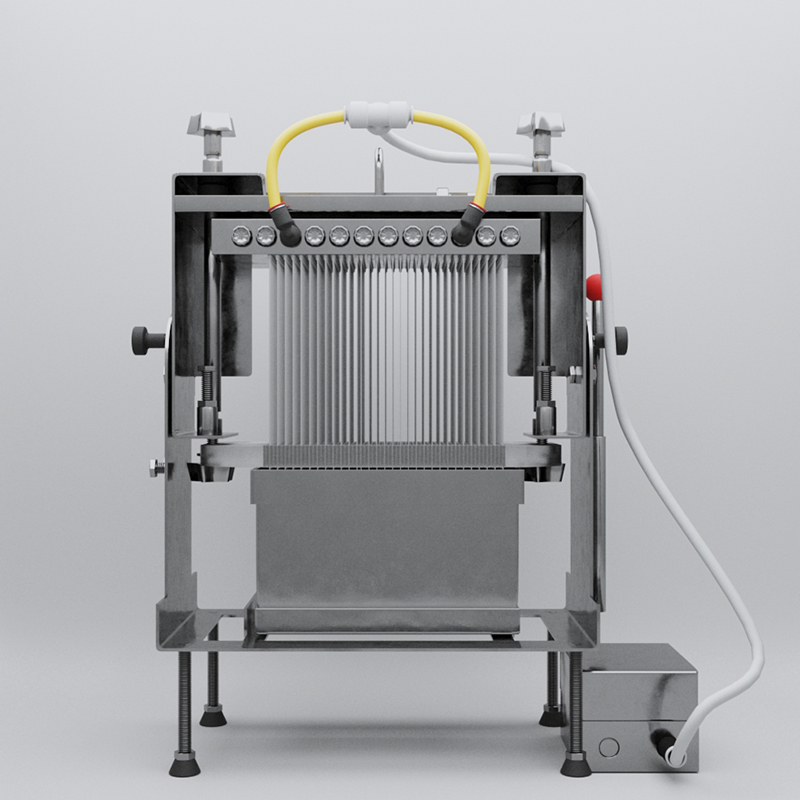

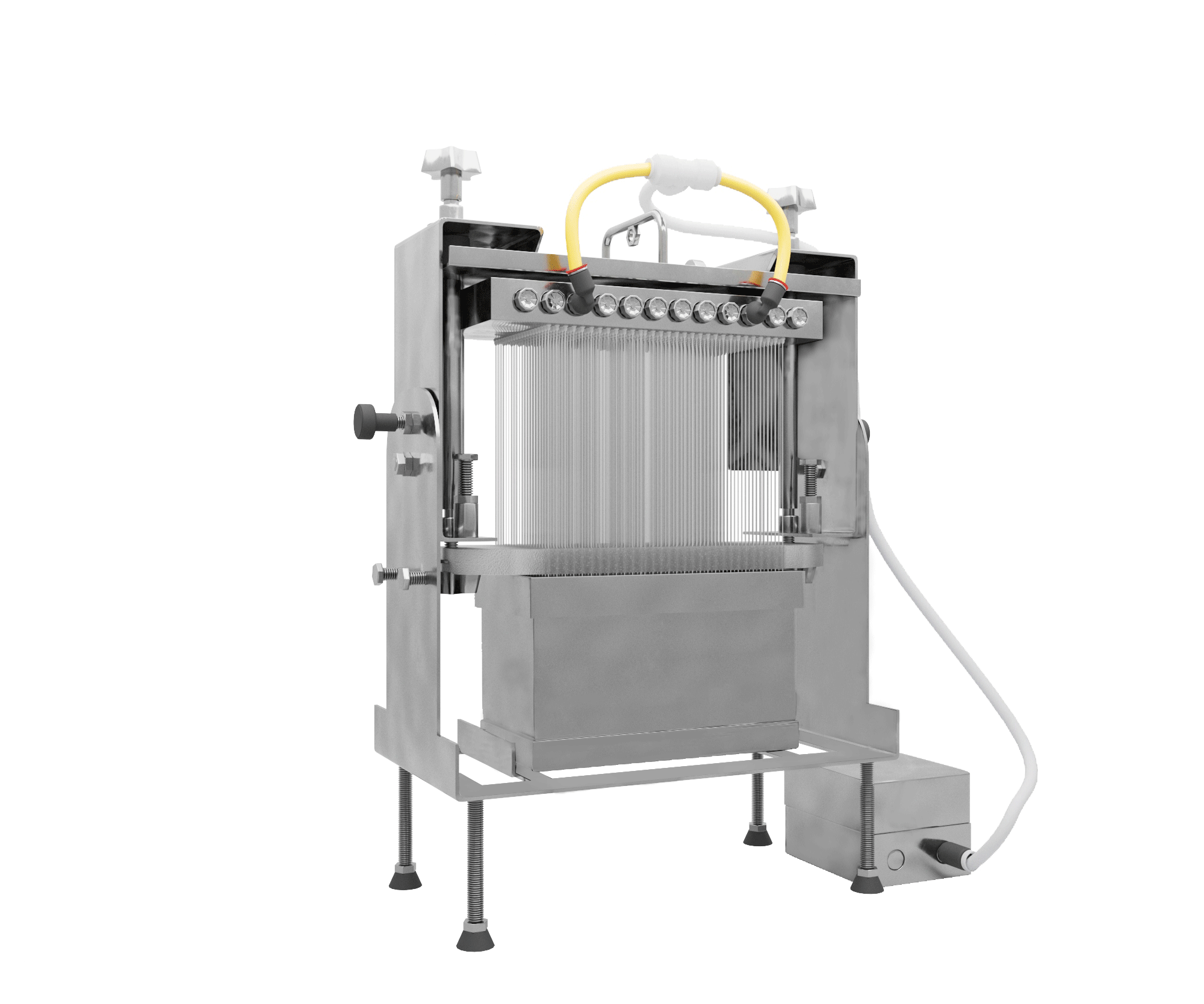

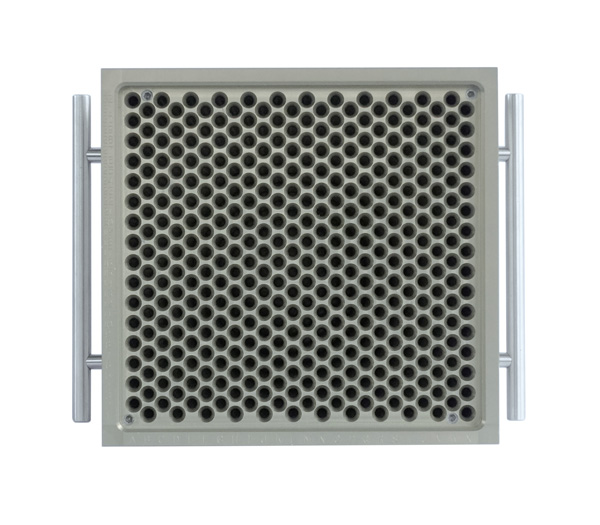

The MSA securely mounts to the manifold of needles so it can interface

with the CLD384 Automatic Clog Detection device.

When the needle matrix is attached

to the MSA

the Clog Detector can be

installed below for

automatic detection

of individual clogged needles.

When needles clog unsightly defects occur,

such as brown meat areas where

no treatment

gas contacted the meat.

Costly damage to tuna increases when multiple

clogged needles cluster together.

The risk of harmful discoloration rises when

TS is used because of its lower CO concentration.

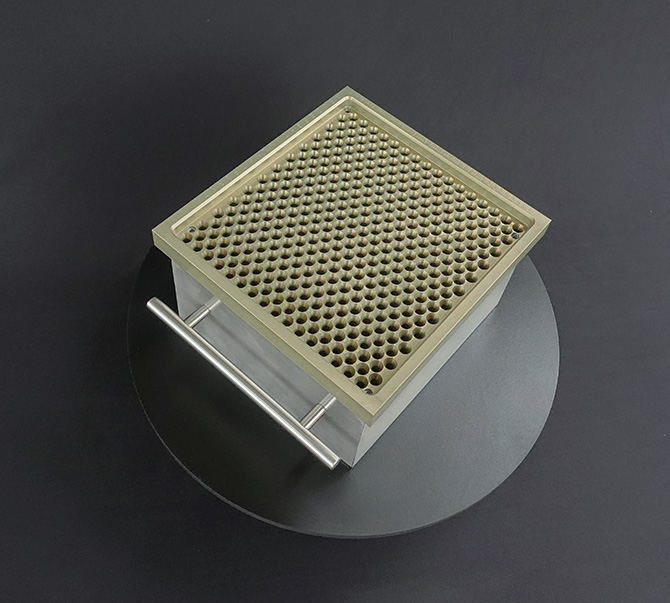

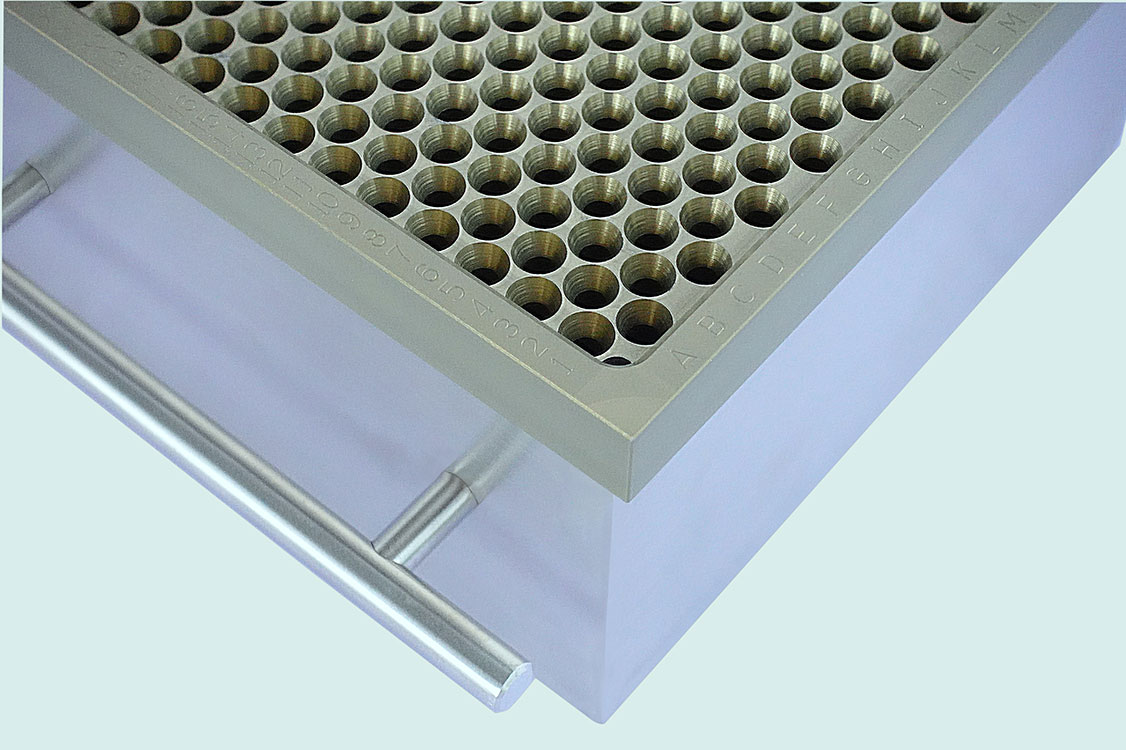

It is very difficult to identify the individual

clogged needles in modern manifolds

with hundreds of needles.

Many processors overcome this problem

of untreated meat

due to clogged needles

by increasing the TS or CO gas dosage.

However, over-gassing will destroy

the meat's quality,

texture, and value.

TUNA TECHNOLOGIES provides the solution of a Clog Detector System that rapidly detects defective needles for replacement.

A manifold with 384 needles is inserted

into Clog Detector.

A report will be generated within minutes

that will identify each individual clogged needle.

The clogged needles are located by

number,

marked and replaced.

In order to have problem-free production, it’s critical to eliminate clogged needles and

maintain

a constant gas flow through the needles to ensure treatment excellence.

TUNA TECHNOLOGIES

is to first introduce a clog detection system

that can identify individual clogged needles in

a manifold, which can be expeditiously replaced.

The turn-around time to service a

manifold matrix

is less than 1 hour

compared to 8 hours

by manual methods.

Labor and wear-n-tear on the needles

and hubs

are reduced.

100% functionality of the manifold

matrix is restored

in minutes,

providing continuous perfect treatment.

Find peace of mind in mass production with Tuna Technologies